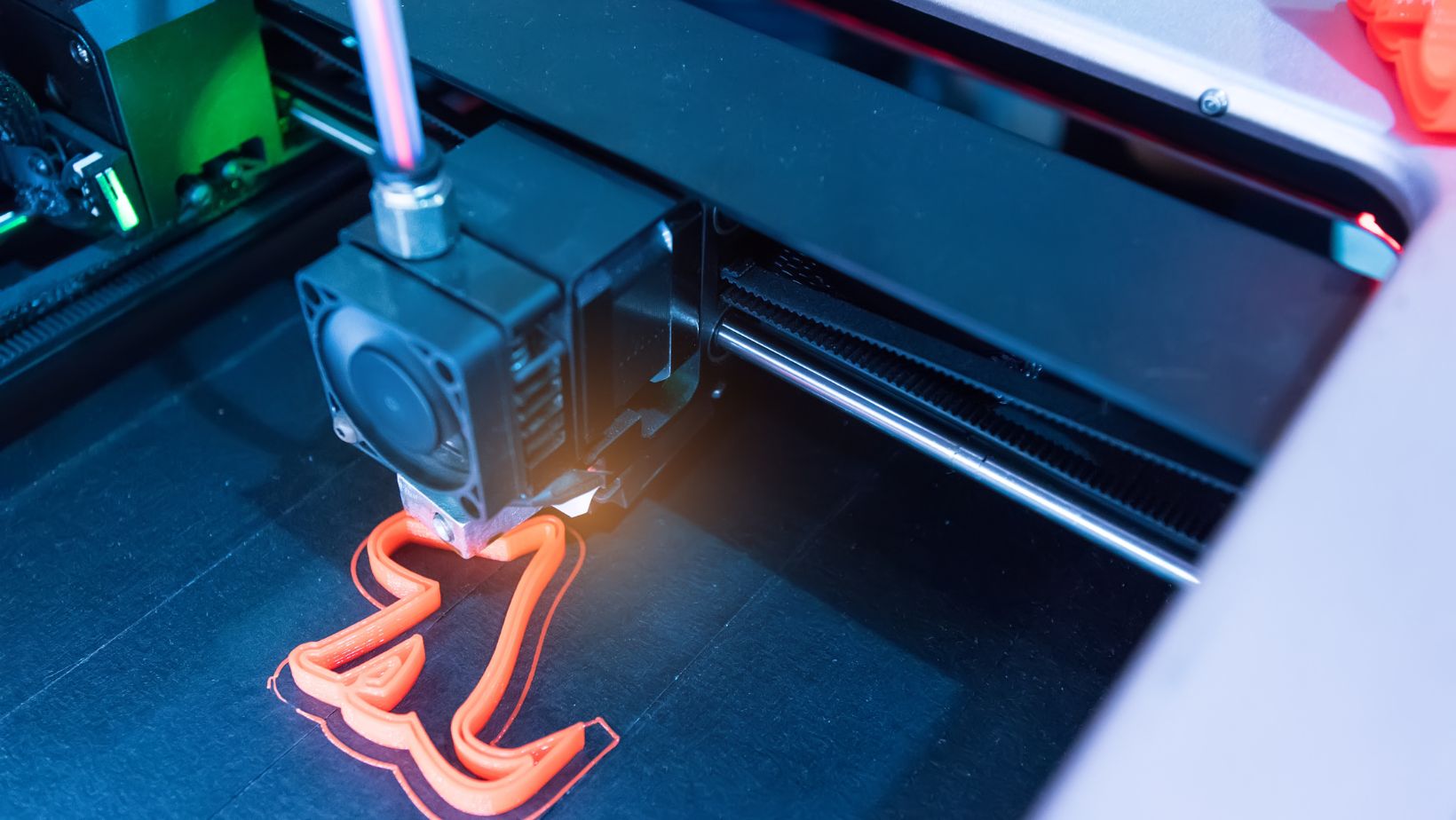

3D printing technology has brought with it a wealth of potential.

From prototyping to product design, this innovation has revolutionized the way we create and produce items.

However, like any advanced tool, 3D printing has its unique challenges.

Understanding these challenges and potential solutions can significantly enhance your 3D printing experience.

In this comprehensive guide, we’ll delve into common 3D print failures and their practical solutions.

Understanding Printer Possibilities

Understanding the capabilities of your 3D printer is fundamental to mitigating common failures.

It’s not just about knowing your printer’s features but also about understanding its limitations and how to optimize its performance.

Optimal Print Settings

First, the print settings of your 3D printer play a significant role in determining the quality of your final product.

Errors in configuration, like temperature, print speed, and layer height, could lead to unsatisfactory results.

Inappropriate temperature settings can cause a multitude of issues.

Too high a temperature might lead to stringing, while too low could prevent adequate filament melting, leading to weak layers.

Getting familiar with your filament material’s temperature ranges and setting them correctly on your printer is essential.

A general guideline is to start with the manufacturer’s recommended settings and adjust incrementally based on the print quality.

The print speed affects how quickly the printer’s nozzle moves while extruding the filament.

A high print speed can decrease the print time, but it may also compromise the quality.

Fast speed might lead to under-extrusion, where the filament does not have enough time to adhere properly.

Conversely, a slower speed increases adhesion, but it could lead to over-extrusion.

Finding the right balance is crucial and often depends on the complexity of the model and the printer’s capabilities.

Layer height is another essential factor.

A smaller layer height leads to finer prints with more detail but increases the total print time.

Larger layer heights are quicker but can lead to visible layer lines. The best strategy is to choose your layer height based on the specific requirements of your print.

Updating Firmware

Updating your 3D printer’s firmware can solve various issues, from improving print accuracy to reducing the chances of print failures.

Manufacturers often release updates that address bugs and provide enhancements that can improve your printer’s overall performance.

It’s important to regularly check for firmware updates and apply them to keep your printer in optimal condition.

However, it’s essential to follow the manufacturer’s instructions precisely during this process to prevent any misconfiguration.

Proper Maintenance

The importance of proper 3D printer maintenance cannot be overstated.

Regular cleaning and inspection of your printer’s key components, like the nozzle, build plate, and filament feeder, can prevent many common print failures.

The nozzle should be cleaned to prevent clogging, which can cause incomplete or failed prints. Methods like cold pulls or nozzle brushes can effectively clean the nozzle.

The build plate should also be kept clean and correctly leveled.

A dirty or uneven build plate can cause first-layer problems, which will affect the entire print. Use a recommended cleaning solution and a reliable leveling process to maintain the build plate.

The filament feeder also requires attention.

Dust and debris in the feeder can mix with the filament and cause clogging or poor-quality prints. Regular cleaning of the feeder will ensure a smooth supply of filament to the nozzle.

Dealing With Print Quality Issues

Despite having optimal printer settings, updated firmware, and proper maintenance, some print quality issues might persist.

These often stem from issues related to the print model and the filament.

Model Errors

Certain issues can be traced back to the model used for printing.

These could include errors in the design file, overhangs without proper support, or complex designs that your printer might struggle with.

Using design software, you can correct these errors before printing. For overhangs and complex designs, consider adding supports or splitting the model into simpler parts.

Filament Problems

The quality and condition of your filament significantly affect the print quality.

A damaged or poor-quality filament can cause problems like inconsistent extrusion, brittleness, and color inconsistency.

Ensure you buy high-quality filament from reputable sources. Also, proper storage of filament is crucial. Keep it in a cool, dry place to prevent moisture absorption, which can degrade its quality.

Overcoming Print Adhesion Issues

Print adhesion issues are common problems that can lead to print failures.

They usually occur when the print does not stick to the build plate properly, leading to warping, shifting, or complete detachment.

Bed Leveling and First Layer Calibration

A well-leveled bed and a properly calibrated first layer are critical to ensure good print adhesion.

If the bed isn’t level or the first layer isn’t calibrated correctly, the print may not stick well, causing it to warp or detach.

Regularly check your bed leveling and adjust the first layer settings for optimal adhesion.

Surface Adhesion Aids

Surface adhesion aids can improve the print’s grip on the build plate.

These include substances like glue sticks, hairspray, or specialty adhesion sheets.

Depending on the material you’re printing with, different adhesion aids might be suitable. Ensure you’re using an aid compatible with your filament and build plate.

Closing Remarks

The world of 3D printing is an exciting one, brimming with endless possibilities.

However, these possibilities come with their unique challenges.

Some of the most common 3D print failures stem from issues like incorrect print settings, outdated firmware, lack of maintenance, model errors, filament problems, and adhesion issues.

Understanding these potential pitfalls and knowing how to address them is vital in reducing print failures and enhancing your 3D printing journey.

Remember, with every print failure comes a valuable learning opportunity, allowing you to continually refine your approach and improve your results.

As you navigate the intricate world of 3D printing, keep these solutions in mind, and you’ll find yourself better equipped to tackle any challenges that come your way.